Background of the project

Background of the project

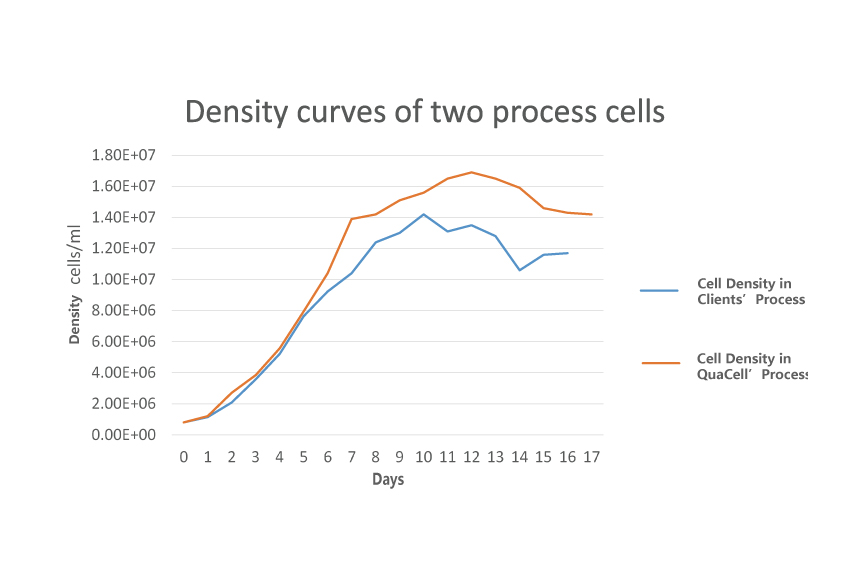

During the fermentation production process

of expression biological products, the peak density, maintenance of activity

rate and the activity rate at the final harvest will directly affect the

structural integrity of the host expression product, the level of Titer

expression, and the stability of the product in the fermentation broth , the

proportion of impurities after receiving the goods and the pressure on the

removal of impurities in downstream purification, etc.

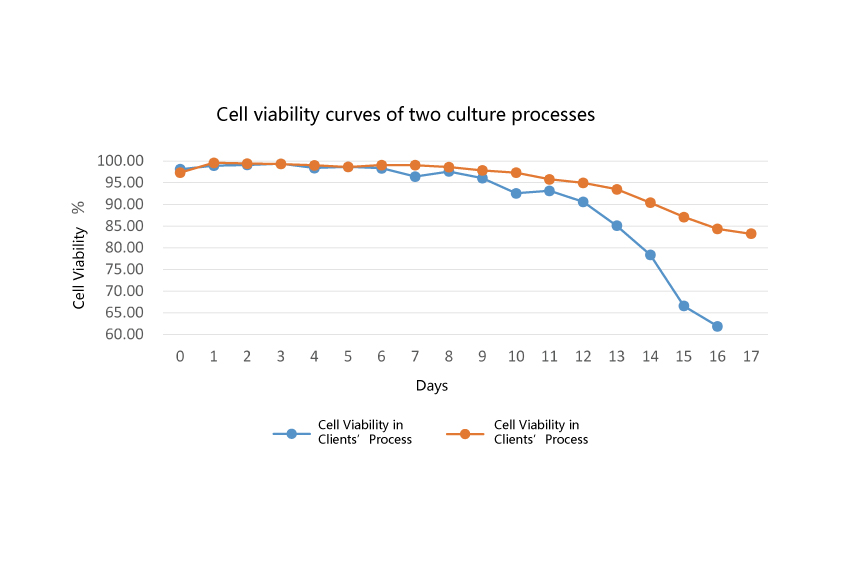

Therefore, without changing the main quality attributes of the product, prolonging the maintenance time of the cell survival rate after the cell density reaches the peak value can maintain a good expression environment, increase the expression level, enhance the stability of the product, and reduce the generation of impurities.

Demand from the customer

Demand from the customer

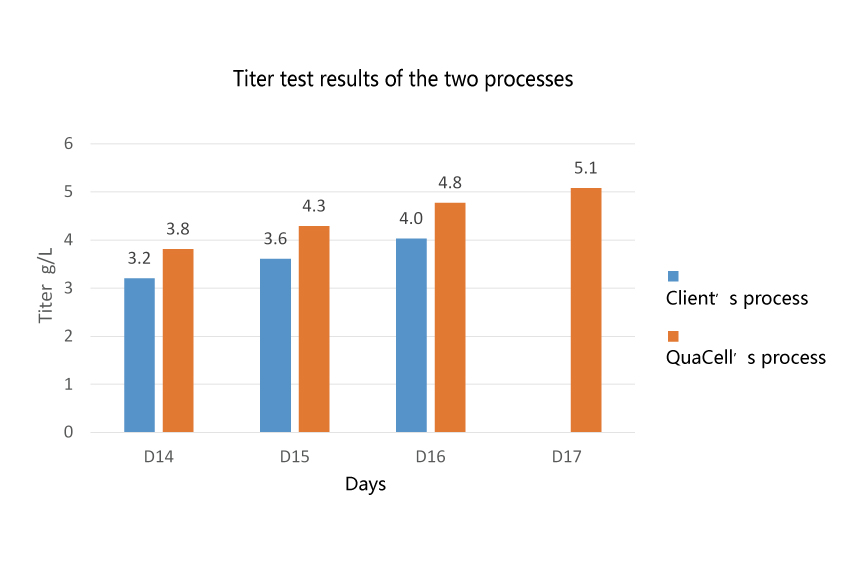

Customer entrusted QuaCell to optimize the cell culture process, expecting the improved process to have a cell viability of more than 20% higher than the original process and an increase of more than 20% in expression.

The cell viability rate was 60% when the sample was received by the original process, and the expression level was 4g/L.

Outcome of the project:

Outcome of the project:

QuaCell optimized the parameters of the customer's process, such as temperature, pH, feed strategy, and culture cycle. After optimization, the cell viability increased by 21.3%, and the expression level increased by 27.5%, which fully met the customer's needs.

Highlights of the project:

Highlights of the project:

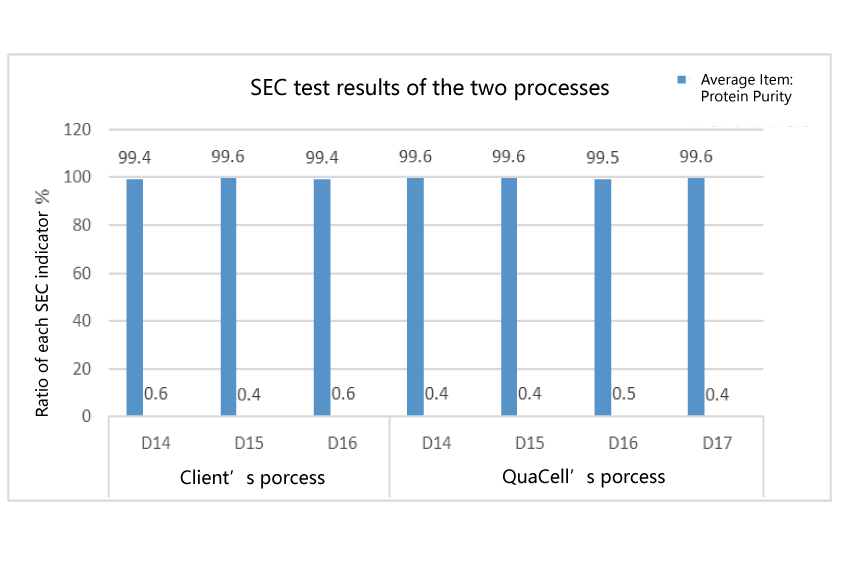

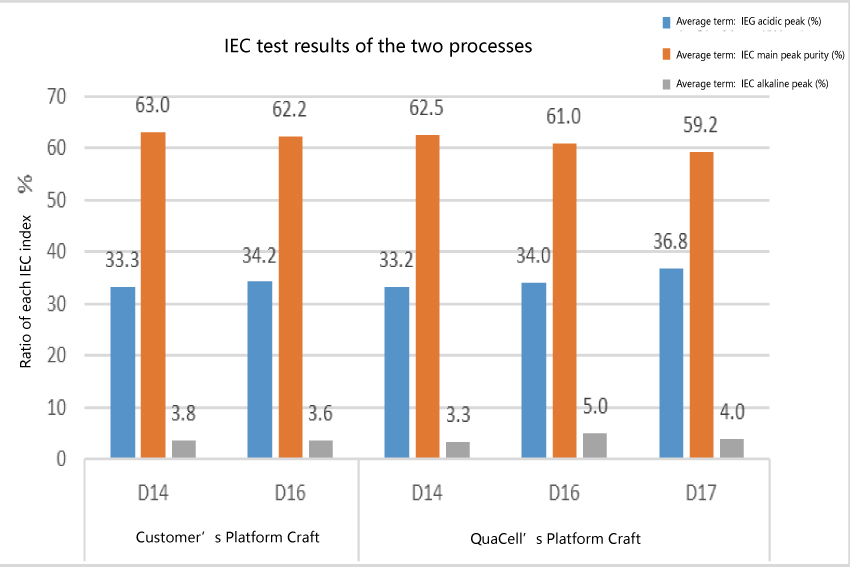

- QuaCell's optimized process achieved better cell growth than the original process, and the cell viability increased by 21.3%;

- QuaCell's optimized culture process

improves the growth and expression of cells, and has less impact on quality.

The results of SEC and IEC are basically consistent with the original process;

- Compared with the original process, QuaCell's process solution has increased the output by 27.5%, which is higher than the target of 20%, greatly reduces the cost pressure of customers.